Toyota Production System In A Nutshell FourWeekMBA

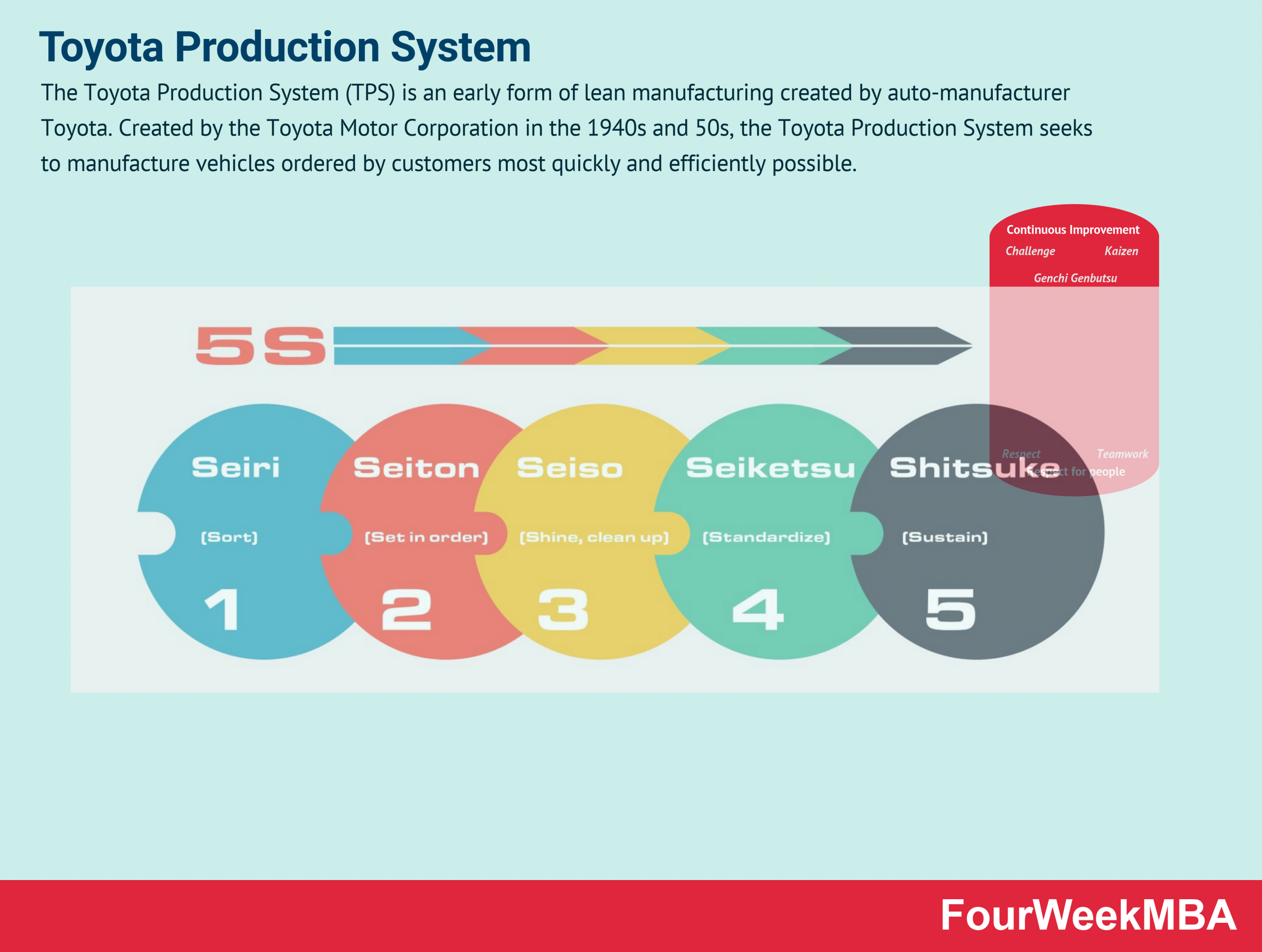

The Toyota Production System (TPS) is a game-changing manufacturing approach that has redefined efficiency and quality. It is a Toyota-developed system that focuses on reducing waste, increasing productivity, and maintaining high-quality standards.

Toyota Production System Books The History & Principles of TPS

The Toyota Production System ( TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. The TPS is a management system [1] that organizes manufacturing and logistics for the automobile manufacturer, including interaction with suppliers and customers.

Share 169+ images toyota production system. In.thptnganamst.edu.vn

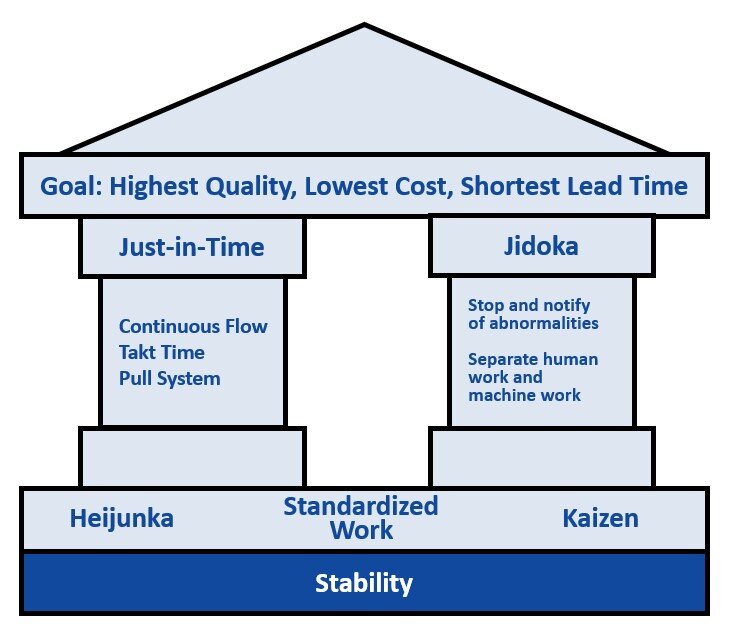

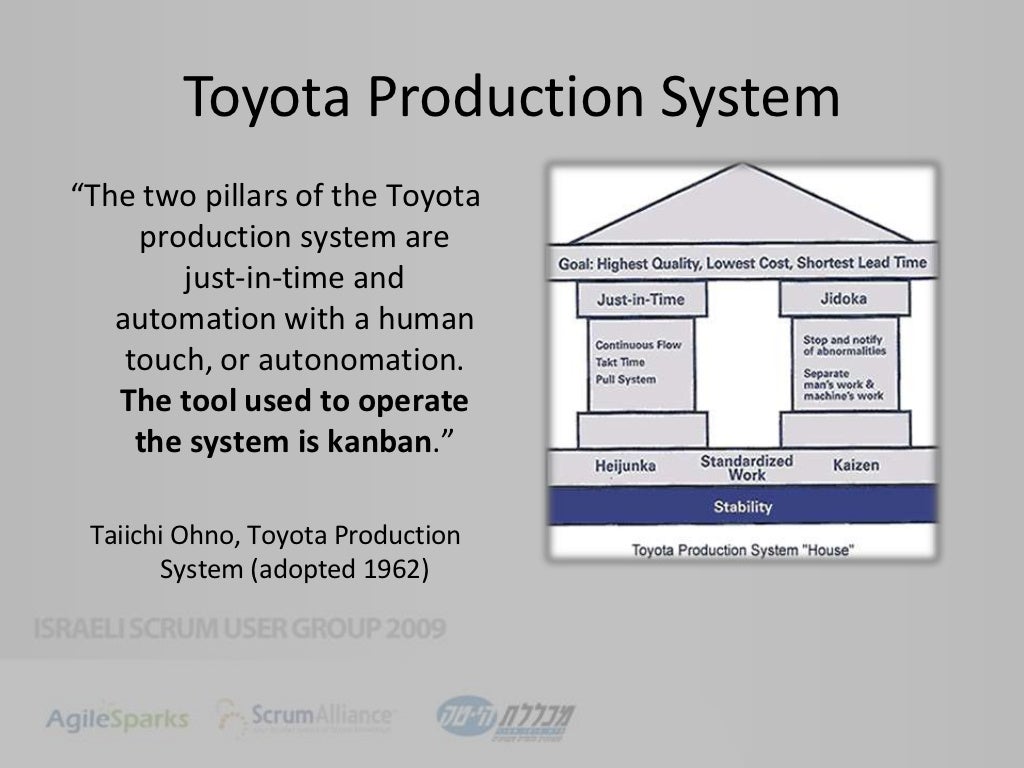

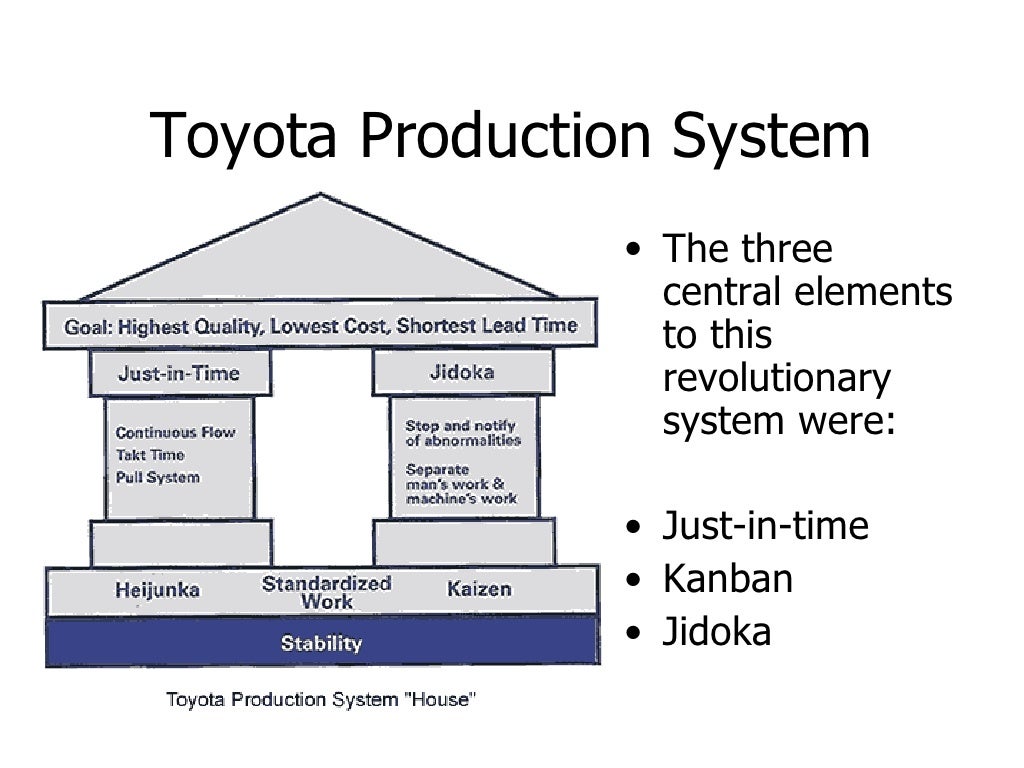

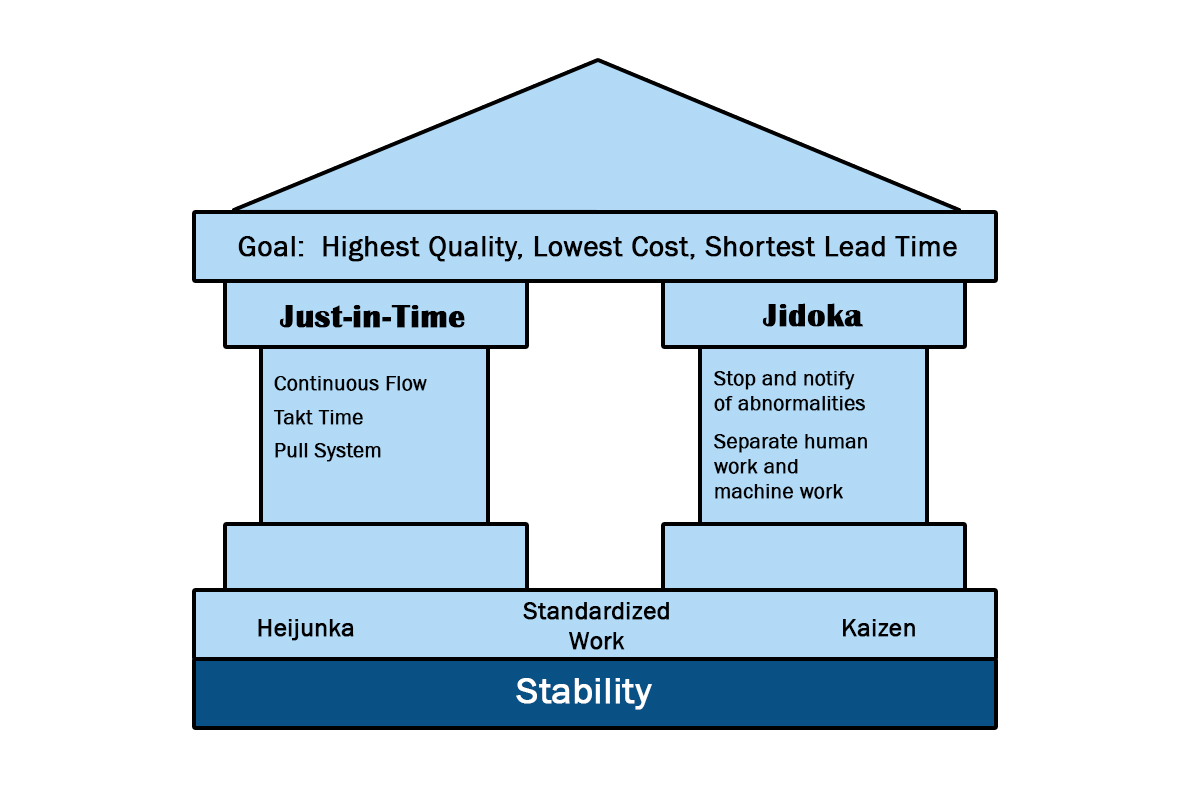

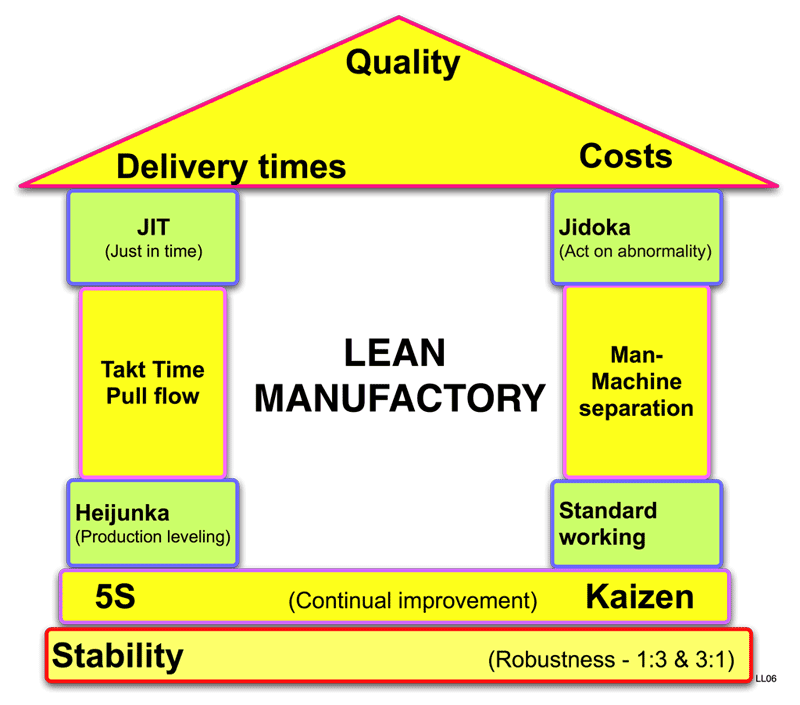

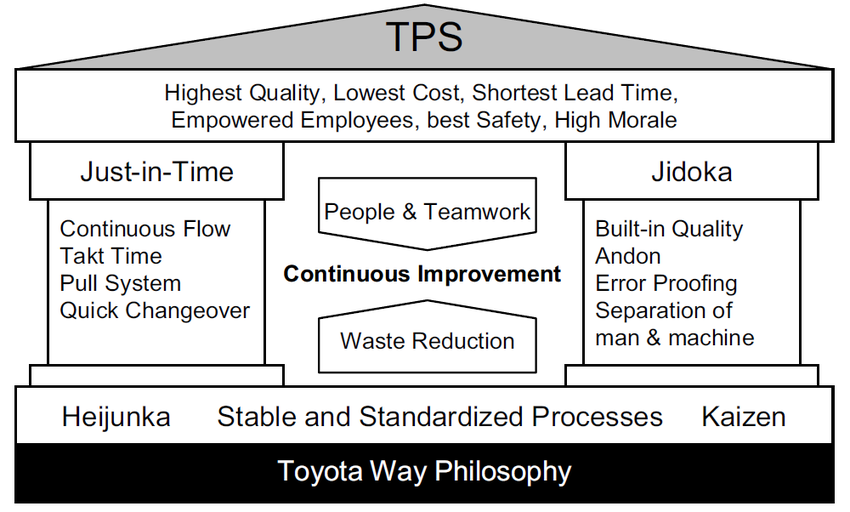

The Toyota Production system is a major precursor of Lean Manufacturing. Founded on the conceptual pillars of 'Just-in-time' and 'Jidoka', it is iconic in Lean

ToyotaProductionSystemLean Peter J Thomson

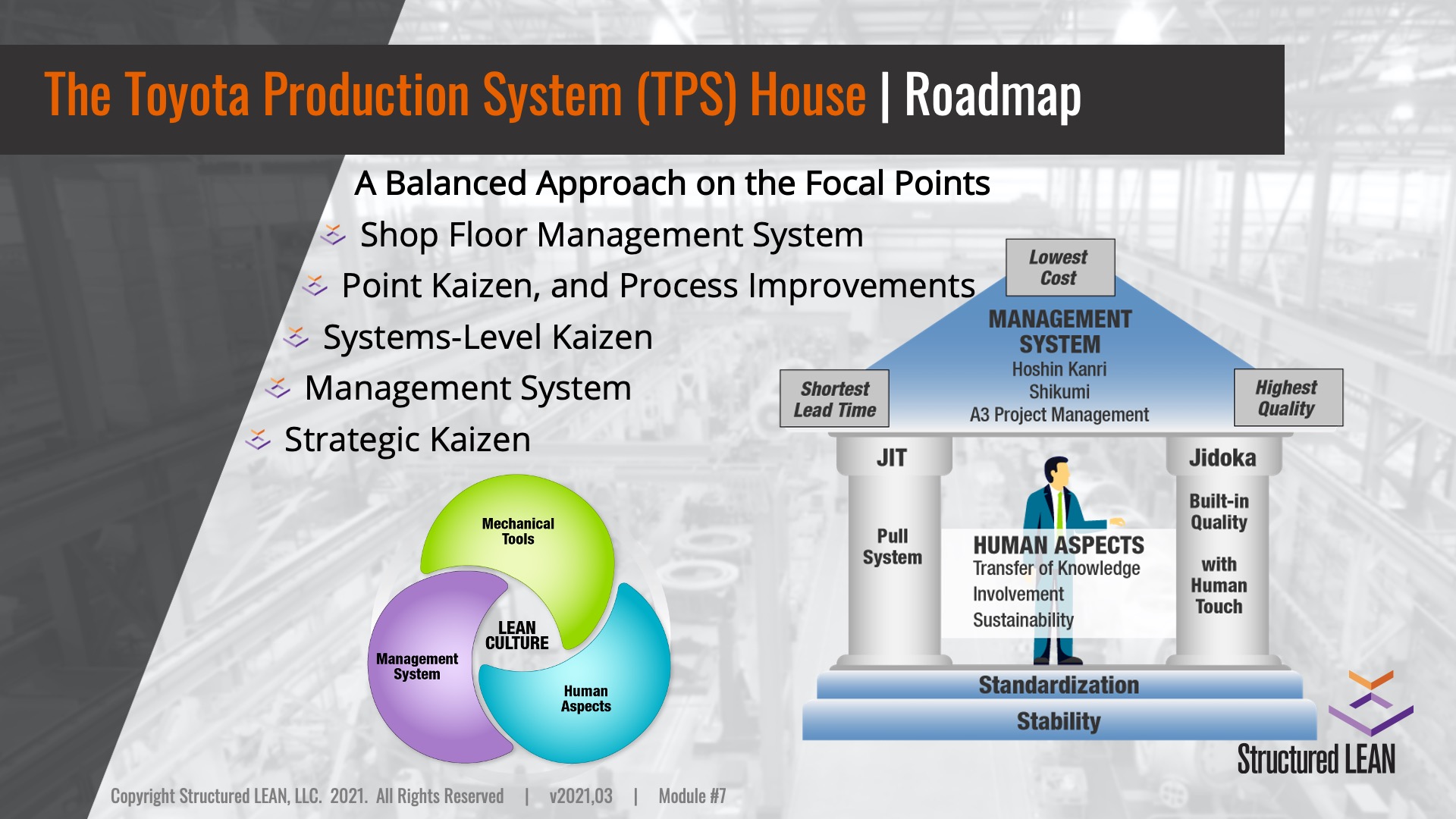

The Toyota Production System (TPS) revolutionized manufacturing worldwide. Today, its application goes beyond manufacturing, impacting transactional processes from healthcare services to software design.

Toyota Production System Maximising production efficiency

The Toyota Production System has long been recognised as a way to eliminate waste and achieve high efficiency. However, its essence is to make work easier and less burdensome for workers, with a focus on creating meaningful work. At the heart of TPS are the concepts of Jidoka and Just-In-Time.

To Understand Lean, You Must Understand More About Toyota — ValueFlo Consulting

The Toyota Production System is built on 14 foundational principles that serve as the pillars of its philosophy. These principles range from long-term thinking and continuous improvement to respecting your extended network of partners and suppliers. They are not standalone ideas but interconnected facets of a cohesive system designed to.

Why the Toyota Production System doesn't always work for others K Bulsuk Full Speed Ahead

TPS Overview 2017 copy COST VS DEFECTS Introduction to the Toyota Production System (TPS) 2.810 T. Gutowski Three Major Mfg Systems from 1800 to 2000 Machine tools, specialized machine tools, Taylorism, SPC, CNC, CAD/CAM 1800 Mass Production at Ford 1900 Interchangeable Parts at U.S. Armories 2000 Toyota Production System

Toyota Production System “The two

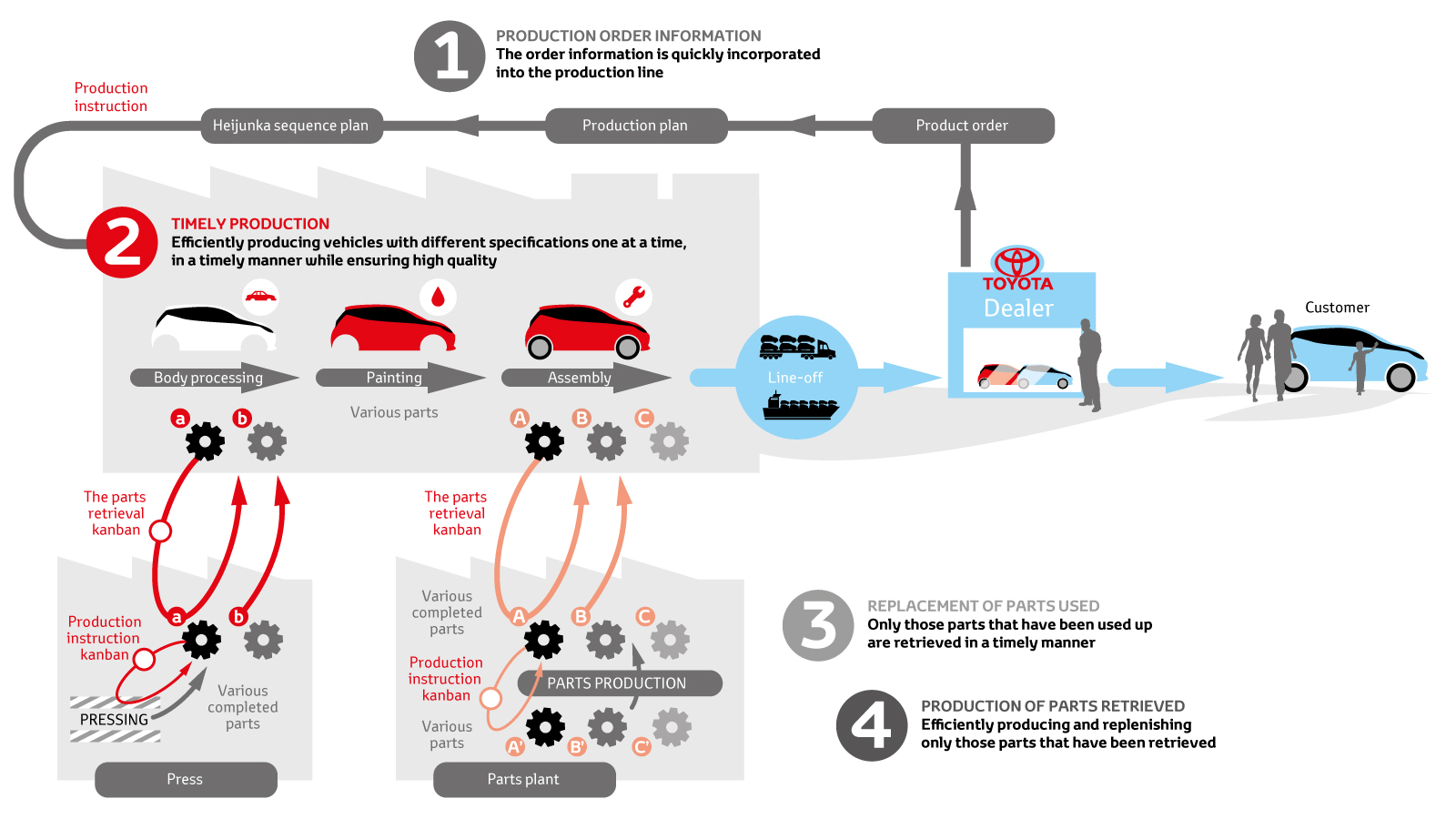

The Toyota Production System (TPS) was established based on two concepts: "jidoka" (which can be loosely translated as "automation with a human touch"), as when a problem occurs, the equipment stops immediately, preventing defective products from being produced; and the "Just-in-Time" concept, in which each process produces only what is needed f.

Toyota production system polizrus

The Toyota Production System ( TPS) is an integrated socio-technical system developed by Toyota (automotive manufacturer) to efficiently organize manufacturing and logistics, including the interaction with suppliers and customers, to minimize cost and waste .

The Toyota Production System House Download Scientific Diagram

Toyota Production System. Basic comcept of the Toyota Production System. Basic concept and history of the TPS, broken down into Just-in-Time and jidoka. Products, Technology. Vehicle Lineage Chart. Vehicle Lineage Chart; Data:Origin of a car's name; Data: Changes in Toyota Trademarks and Emblems; Data: Motor Shows and Toyota ;

The Personal Lean Mohammed Hamed Ahmed Soliman What Toyota Production System is Really About?

Toyota Production System (TPS), originally called "Just-in-Time production", was developed by Toyota to organize their manufacturing operations including logistics, supplier management, up to customer delivery. Its basic concept is the reduction of cost through elimination of waste and optimization of machine and human capabilities.

Toyota Production System The three

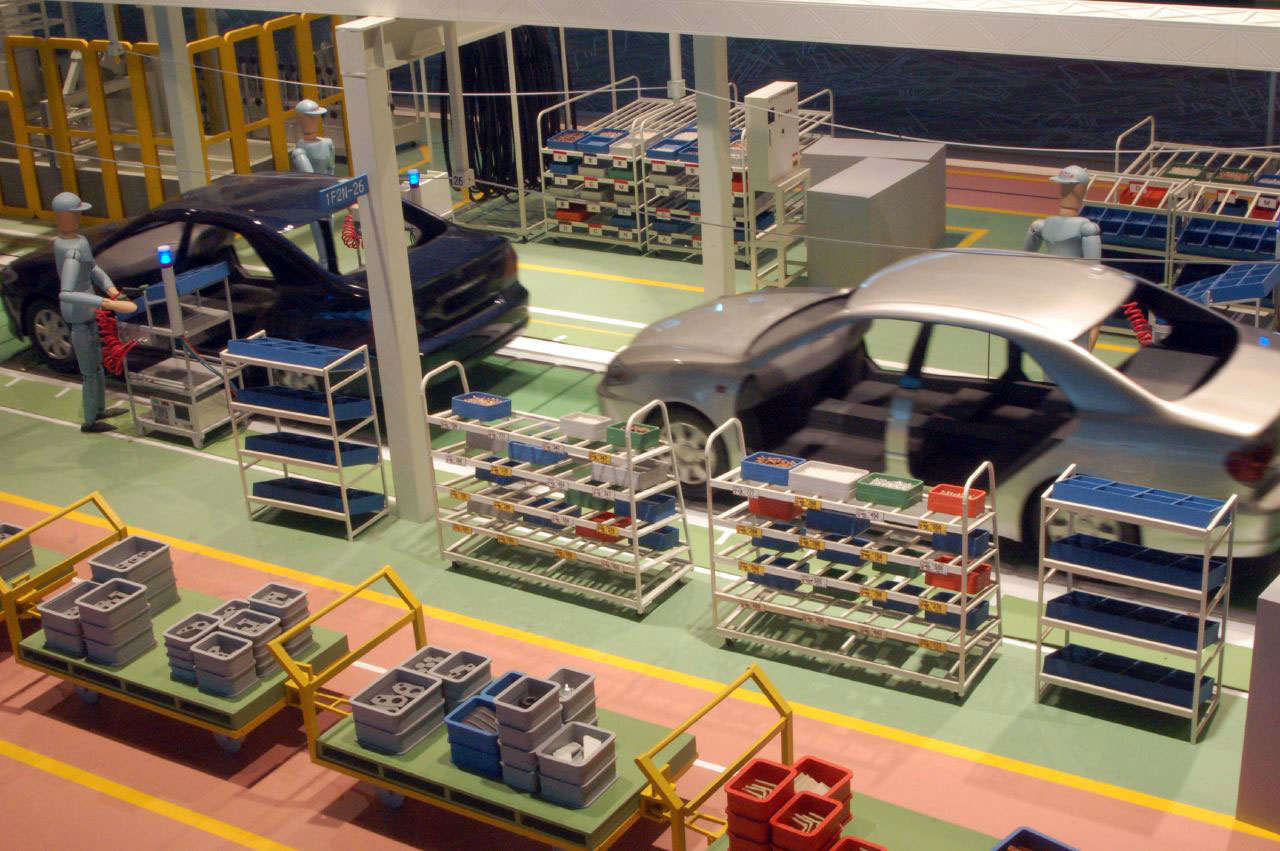

Toyota Motor Corporation's vehicle production system is a way of "making things" that is sometimes referred to as a "lean manufacturing system" or a " just in time (JIT) system", and has come to be well known and studied worldwide.

What to Learn from the Toyota Production System

The production system developed by Toyota Motor Corporation to provide best quality, lowest cost, and shortest lead time through the elimination of waste. TPS is comprised of two pillars, just-in-time and jidoka, and often is illustrated with the "house" shown at right.

Apa itu Toyota Production System? kaizenpro

In the Toyota Production System, the term Jidoka or autonomation is used instead of automation. Jidoka is the concept of preventing defective products by automatically stopping a machine when an abnormality occurs. This eliminates the need for a person to watch over machines all the time, thereby improving productivity.

Secrets of the Toyota Production System Rever

The Toyota Production System emerged because it showed itself to be both more resilient and more adaptable than traditional mass-production methods. For decades prior to the development of the Toyota Production System, America had cut costs by mass producing fewer types of cars. It was an American work style — but not a Japanese one.

Toyota Production System Quotes. QuotesGram

TOYOTA PRODUCTION SYSTEM BASIC HANDBOOK INTRODUCTION This handbook is intended to function as a simple guide that introduces key concepts related to the Toyota Production System. It is not intended as a complete reference manual or an implementation guide.